Shipping goods to Amazon FBA requires understanding specific pallet specifications to ensure smooth operations. Knowing the Amazon FBA pallet requirements can optimize your shipping process, reduce costs, and avoid unnecessary delays. This guide will walk you through essential details, from standard pallet dimensions to best practices for packing, so you can meet Amazon’s standards effortlessly. Let’s dive into the crucial aspects of Amazon FBA pallet specifications.

Table of Contents

Understanding Amazon FBA Pallet Requirements

Amazon FBA requires adherence to specific pallet requirements to ensure smooth processing within their fulfillment centers. Understanding these requirements can help you optimize your shipping efficiency and reduce potential delays.

Pallet Dimensions and Weight Limits: The standard pallet size accepted by Amazon is 40 x 48 inches with a maximum height of 72 inches, including the pallet. The total weight must not exceed 1,500 pounds. Adhering to these dimensions and weight limits ensures that your shipment will be accepted without issues.

Importance of Pallet Quality and Material: When it comes to pallet quality, using durable and sturdy pallets is crucial. Amazon accepts both wood and plastic pallets, but they must be in good condition, free from damage or contamination. Qualitative pallets protect your products during transit and handling.

Avoiding damage and ensuring that the palletized shipments can be handled by forklifts or pallet jacks within Amazon’s fulfillment centers is vital. This also minimizes the risks of accidents or product damages during the logistics process.

Proper Labeling and Documentation: Ensure that each pallet is properly labeled with the necessary shipping labels, including both the FBA shipment ID and the Pallet label. Incorrect or missing labels can lead to processing delays. It’s also required to have all necessary documentation, such as the Bill of Lading (BOL) and any customs paperwork, readily available.

Make sure that your labels are scannable and securely attached to the pallets. This will streamline the inbound process and increase the efficiency of your shipment into Amazon’s network.

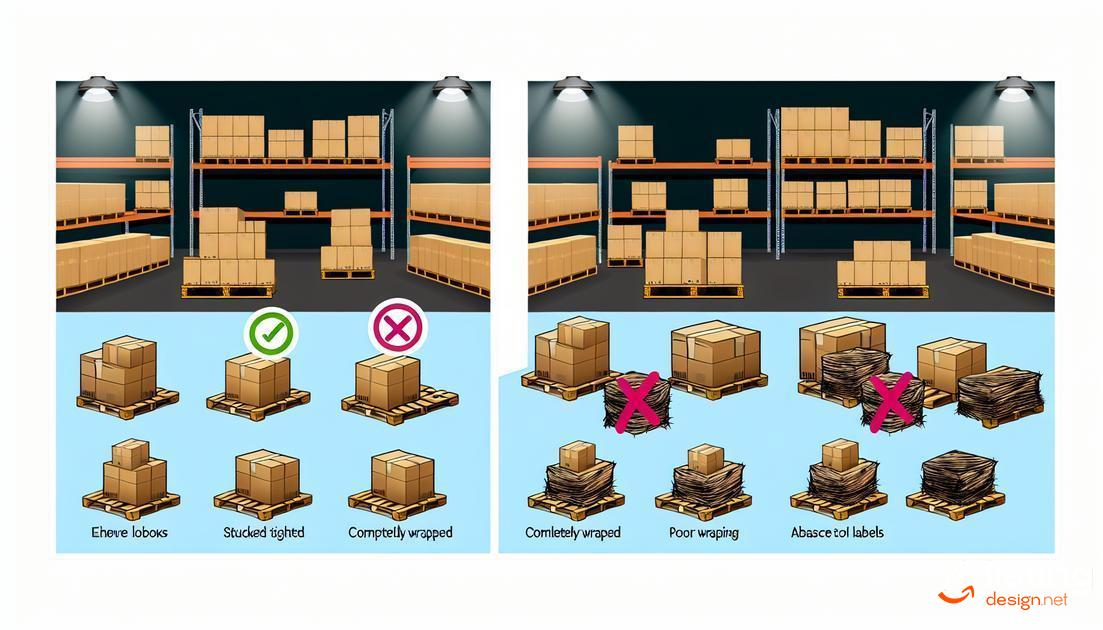

Best Practices for Packing and Stacking: Efficient packing and stacking techniques are necessary for optimizing space and ensuring safety. Distribute the weight evenly and avoid overhanging items. Secure your load with stretch wrap and corner boards to reinforce stability.

Utilizing these best practices will maximize space usage, protect your products, and reduce the risk of shifting or toppling during transportation.

Common Mistakes to Avoid: One common error is using non-compliant pallets or exceeding weight limits. Mislabeling or failing to label the pallets can result in delayed processing. To avoid these mistakes, always double-check that your shipment conforms to Amazon’s FBA requirements.

Compliance with these standards helps you avoid additional fees and ensures a smoother fulfillment process.

Standard Pallet Dimensions and Weight Limits

Standard pallet dimensions and weight limits are crucial when preparing shipments for Amazon FBA. The typical size for a standard pallet in North America is 48 inches by 40 inches. These dimensions are widely accepted in the shipping industry and fit well within most transportation and warehousing systems. When using pallets, it is essential to adhere to weight limits to avoid damages and ensure safe handling. The standard weight limit for a wooden pallet is approximately 2,500 pounds, though this can vary depending on the material and construction quality.

Overloading a pallet

can lead to structural failure and potential loss of goods. To optimize shipping efficiency, make sure to distribute weight evenly across the pallet. This prevents tilting or collapsing during transit. Avoid stacking items too high; usually, pallets should not exceed 60 inches in height to maintain stability.

When preparing pallets for Amazon FBA, double-check that dimensions and weight limits comply with Amazon’s specific guidelines to prevent any unnecessary delays or costs. Properly sized pallets maximize use of space, contributing to efficient shipping and handling processes.

Importance of Pallet Quality and Material

The quality and material of pallets directly impact the efficiency and safety of shipping with Amazon FBA. Using high-quality pallets ensures that products remain secure during transit, reducing the risk of damage and potential returns. Ensuring that pallets are made from sturdy materials, such as durable wood or plastic, can withstand the weight and handling stress, thus maintaining the integrity of the shipment.

Material selection is equally important. Wooden pallets are commonly used due to their strength and availability, but they must be treated to meet international shipping standards. Alternatively, plastic pallets offer a lightweight and reusable option and are less likely to harbor pests, therefore, meeting strict Amazon FBA requirements.

Choosing the right pallet quality and material can also influence warehouse efficiency. High-quality pallets facilitate easier handling with forklifts, reducing potential delays during loading and unloading. Additionally, using standardized and robust pallets can help in maximizing storage space and ensuring better organization within the warehouse.

Ultimately, investing in good pallet quality and selecting the appropriate materials for your shipping needs is crucial for optimizing your supply chain and maintaining compliance with Amazon FBA standards.

Proper Labeling and Documentation for Pallets

Proper Labeling and Documentation for Pallets

Proper labeling and documentation for pallets is crucial for smooth shipping operations in Amazon FBA. Every pallet needs to have the correct labels and documents to avoid delays and ensure compliance.

Label Placement and Information

Labels should be placed on all four sides of the pallet and be easily accessible. Each label should include important details such as the FBA shipment ID, product type, and quantity. This helps Amazon’s staff quickly identify and process your pallets.

Documentation

Include a packing list and any necessary shipping documents. The packing list should match the items on the pallet. Accurate documentation helps to avoid issues such as inventory discrepancies.

Make sure labels are durable and attached securely to withstand transit. Using high-quality label adhesives prevents labels from peeling off or becoming unreadable.

Using barcodes on labels can streamline the identification process, making it faster for Amazon to scan and check-in your pallet. Assemble all required documents in a clear, plastic sleeve attached to the pallet.

Best Practices for Packing and Stacking

Optimize Your Packing Process

Ensuring your boxes are well-packed is crucial for both safety and cost efficiency. Use durable boxes that can withstand stacking pressure and handle the transit journey without damage.

Follow Amazon’s Guidelines

Amazon has specific stacking guidelines to make sure your products are safe during transit. Make sure to stack boxes neatly, with heavier items at the bottom and lighter items on top. Avoid overhanging items to prevent damage or rejection.

Use Pallet Patterns

Efficient pallet patterns help in maintaining the stability of your load. Consider using brick-stacking or column-stacking patterns based on the nature of your packages. Proper patterns can significantly enhance load stability.

Utilize Protective Materials

Adding stretch wraps, corner boards, and strapping can secure your pallets and reduce the movement of items during shipping. This helps in minimizing the risk of product damage and ensures your shipment meets Amazon’s FBA requirements.

Regular Checks and Inspections

Before dispatching pallets, conduct thorough inspections to ensure compliance with Amazon FBA specifications. This includes checking for proper packing, stacking, and labeling on each pallet.

Common Mistakes to Avoid When Preparing Pallets

Avoiding Common Mistakes When Preparing Pallets is Crucial for Efficiency and Compliance. Missteps can lead to costly delays, penalties, or even rejected shipments, which can ultimately harm your business. Here’s a closer look at some common errors and how to avoid them:

- Improperly Securing Contents: Failing to use sufficient wrapping or strapping can cause items to shift during transit, leading to damaged goods. Ensure all items are tightly secured and uniformly packed.

- Overloading Pallets: Exceeding weight limits can compromise pallet integrity and make handling difficult. Always adhere to Amazon’s weight restrictions and use pallets rated for the load they will carry.

- Incorrect Label Placement: Labels that are not placed correctly or are poorly printed can result in misrouted or delayed shipments. Make sure labels are clearly visible and securely attached to the pallet.

- Poorly Stacking Items: Uneven stacking can lead to instability, making the pallet prone to tipping. Distribute weight evenly and use interlocking stacking methods to enhance stability.

- Ignoring Pallet Quality: Using damaged or low-quality pallets can cause collapse during handling. Inspect pallets before use and replace any that show signs of damage or wear.

By avoiding these common mistakes, you can improve your shipping efficiency and ensure compliance with Amazon’s stringent requirements.

How to Choose the Right Shipping Partner

Choosing the right shipping partner is crucial for optimizing your Amazon FBA operations. First, evaluate the partner’s experience with Amazon FBA shipments. They should be well-versed with Amazon’s specific requirements and guidelines.

Look for reliability and track record

. Check reviews and ask for references to ensure they have a history of on-time and damage-free deliveries.

Next, consider the shipping partner’s network and reach. They should have a strong logistics network that can cover your key markets efficiently. Also, inquire about their customer support and communication capabilities. A partner with robust support can help resolve issues quickly and keep you informed throughout the shipping process.

Another important factor is cost. Compare rates and services of different shipping partners. Look for transparency in pricing and avoid hidden charges. Additionally, understand their insurance options and claims policy to secure your shipments against potential losses or damages.

Finally, analyze their technological capabilities. A good shipping partner should offer tracking solutions and integration with your existing systems to streamline operations and improve efficiency.

Cost-Effective Pallet Shipping Strategies

Cost-Effective Pallet Shipping Strategies

Utilizing cost-effective pallet shipping strategies is crucial for maintaining your profit margins. One key approach is consolidating shipments to reduce the number of pallets shipped. This minimizes transportation costs and maximizes space utilization.

Another strategy involves optimizing the pallet configuration. Make sure to stack products efficiently, ensuring stability while maximizing pallet space. Use high-quality but cost-effective materials for pallets to prevent damage during transit.

Taking advantage of seasonal shipping discounts offered by carriers can also help lower costs. Additionally, consider using a mix of LTL (less than truckload) and FTL (full truckload) shipping based on the volume of your goods.

Negotiating contracts with shipping partners can lead to favorable rates. Building a long-term relationship with a reliable carrier often results in better prices and service. Lastly, invest in technology to track shipments and streamline logistics processes. This not only improves efficiency but also helps in identifying areas where costs can be reduced.